Why Cellulose Insulation? Why use the Insulation Guys?

Higher R-Value 33%

No other material normally used in attics today insulates better than Cellulose. This revolutionary product has an R-value that's as much as 70% higher than blown fiberglass. That's why a Cellulose home is superior in comfort, efficiency of energy use and economy.

|

The Best Value Inch For Inch

Traditional insulation products settle or compact over time, so homeowners often end up with less than they paid for. Cellulose is different. It's installed based on its stabilized settled density, so it stays put. Inch for inch, year after year, a Cellulose home is your best value. |

No Convective Energy Loss

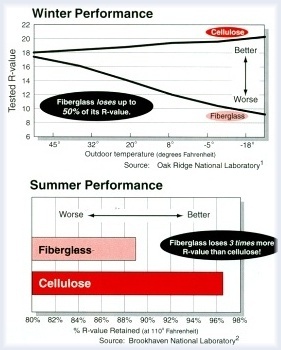

Cellulose has a higher initial R-value than fiberglass, but there's more. Recent scientific tests have proven that convection causes fiberglass to lose as much as 50% of its R-value in cold weather. Simply stated, convection transfers energy by air movement inside the insulation from the warm side to the cold side.

Cellulose's shorter, natural fibers form a highly efficient thermal barrier to virtually eliminate convection. With a higher initial R-value that stays higher in cold weather, it's easy to see why a Cellulose home is so much better to build, and to own. |

|

HIGHER R-VALUE |

70% higher

R-Value |

One inch

of blown

fiberglass

insulation

|

One inch

of Cellulose

insulation | |

NO HEAT MIGRATION

Inside fiberglass (left), heat travels by convective currents to the cold side. The long glass fibers are too far apart to prevent it. Clean cellulose (right) has shorter fibers which form a high thermal density. Convective currents cannot form. |

Fiberglass Insulation Fiberglass Insulation |

CLEAN Cellulose Insulation CLEAN Cellulose Insulation |

|

|

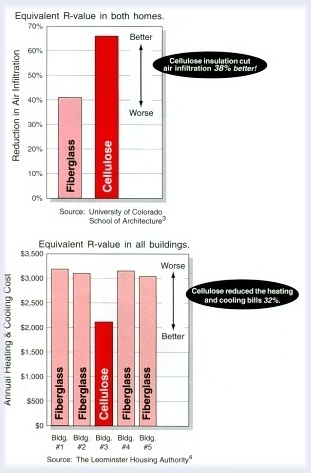

SEALS TO CONSERVE ENERGY

No cracks, no voids. Cellulose completely fills in around wood framing members, electrical wiring, plumbing and other irregular shapes between joists. The highly efficient, natural fiber barrier blocks air movement and heat loss. Recent tests by the University of Colorado proved it. A home insulated with cellulose, including wall cavity spray insulation, used up to 38% less energy than an identical home insulated with fiberglass batts. Reducing energy costs is important; that's why a Cellulose home is an energy-conserving home. |

A home insulated with cellulose can use up to 38% less energy than an identical home insulated with fiberglass batts. |

SUPERIOR FIRE SAFETY

Cellulose's highly efficient thermal barrier actually repels intense heat. It outperforms fiberglass by forming a barrier to protect other, more combustible construction materials. And Cellulose's Class 1 fire rating meets or exceeds all requirements of local and national building codes.

When it comes to fire safety, Cellulose is one of the safest insulation materials you can use.

|

|

SUPERIOR HEALTH SAFETY

Today, homeowners are concerned about a possible link between cancer and glass fibers. They're looking for an insulation alternative they know to be safe.

|

Cellulose is that alternative, because it's made from natural, noncarcinogenic fibers. Homeowners will breathe easier knowing there's Cellulose air in their homes.

|

The Hot Topic

Cellulose vs. FiberglassThe following is a summary of an extensive Natural Resources Defense Council (NRDC) report. The NRDC is a non-profit environmental membership organization with over 300,000 members and contributors nationwide:

The NRDC has concluded the following:

- Cellulose insulation manufactured from recycled paper is the least polluting and most energy efficient insulation.

- Cellulose has the highest post-consumer recycled content. The fiberglass industry averages 35% recycled glass, while the cellulose industry averages a minimum of 75% recycled content.

- It takes more than 10 times as much energy to produce fiberglass insulation as cellulose insulation.

- Due to air circulation and natural convection, the R-value of blown-in fiberglass insulation decreases by as much as 50% as the temperature drops from 45 degrees F to 18 degrees F.

- Cellulose has better resistance to air flow and prevents the upward movement of air caused by temperature differences (the R-value of cellulose actually improves during cold weather).

- Substantial and well-documented public health threats are associated with fiberglass.

- No adverse health effects from cellulose insulation have been identified.

Cellulose is non-toxic. Biologically, cellulose is innocuous.

~ Dr. Arthur Furst, Toxicologist

Why Cellulose?

- Cellulose that has been properly installed in your walls will not settle.

- Cellulose is non-corrosive to steel, copper and aluminum.

- Cellulose will not lose it's energy saving abilities over time.

- Cellulose will not rot, decay or mildew, and it does not support fungus or mold growth.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Will My Choice of Insulation

Really Effect My Monthly

Heating & Cooling Bills?

YES!

Different insulations are made from fundamentally different materials. Tests at Oak Ridge and Brookhaven National Laboratories and the University of Illinois reveal that insulations with the same laboratory R-values do not perform equally in real homes. Researchers found that the effective R-value of blown fiberglass plunges during cold weather, while the effective R-value of cellulose actually increases. The researchers also discovered that summer temperatures offer no relief for fiberglass, since its effective R-value withers then, too. Different insulations are made from fundamentally different materials. Tests at Oak Ridge and Brookhaven National Laboratories and the University of Illinois reveal that insulations with the same laboratory R-values do not perform equally in real homes. Researchers found that the effective R-value of blown fiberglass plunges during cold weather, while the effective R-value of cellulose actually increases. The researchers also discovered that summer temperatures offer no relief for fiberglass, since its effective R-value withers then, too.

Utility bills were 32% lower in the cellulose insulated building.

~ Leominster Housing Authority

Cellulose helps keep your home warmer in the winter, cooler in the summer, blocks air infiltration, and saves you money!

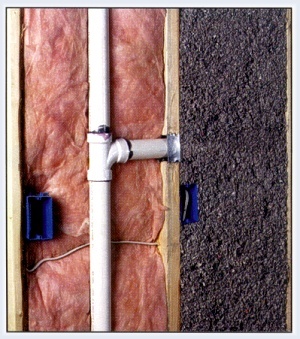

Do Different Installation Methods

Make a Difference?The walls, ceilings, and floors of your home are full of odd shaped cavities and obstacles like plumbing, air ducts, and wiring. For your insulation to work effectively, it must completely fill around these obstructions without gaps or voids.

Installation is critical in determining how insulation performs in your home. How well does it fit in different size wall cavities and around countless obstacles? Is it cut and patched in? Or is it custom fit?

Cellulose insulation is sprayed or blown into walls, conforming to your home and surrounding you and your family with a seamless insulation system. Fiberglass batts, on the other hand, are cut and pieced together, leaving gaps, voids & areas of compression.

A Difference You Will See, Feel, and Enjoy

Installing cellulose insulation in your existing home is one of the best decisions you can make for yourself and your family.

Walls are fully and tightly insulated, forming a monolithic thermal barrier.

No more gaps. No more voids. No more drafts. Just years of comfort.

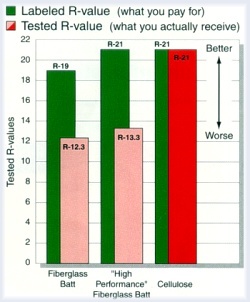

Getting What You Paid For

Tests conducted by a fiberglass manufacturer reveal that the actual performance of batts can be 14% to 45% less than their labeled R-value when gaps and voids associated with normal batt installation are considered. With cellulose insulation, you receive the insulation performance you paid for.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

The Colorado Study

Energy Conservation vs. Fiberglass

In December 1989 and January 1990 the University of Colorado at Denver School of Architecture and Planning studied the energy conservation efficiency of two test buildings that differed only in the insulation systems that had been installed.

Building "A" was insulated with 5.5 inches of sprayed-in cellulose in the walls and R-30 of loose-fill cellulose in the ceiling. Building "B" received R-19 unfaced fiberglass batts in the walls and R-30 kraft-faced batts in the ceiling.

Over the two-month period a number of different tests and measurements were performed.

Here's what the University researchers learned.

- In spite of the fact that tests showed Building "B" was about 12% tighter than Building "A" in the uninsulated state, after insulation was installed building "A" was far tighter than "B". Calculations showed that cellulose tightened the building 36% to 38% more than fiberglass.

- An overnight heat loss test revealed that after nine hours (midnight to 9 a.m.), the cellulose-insulated building was 7 degrees F warmer than the fiberglass building.

- Most significantly, after three weeks of monitoring the cellulose-insulated building had used 26.4% less heat than the fiberglass building.

In their statement of conclusions the researchers note that results suggest cellulose performs as much as 38% better than fiberglass. The performance advantage of cellulose in temperate climates appears to be about 26%, and the report projects that "this benefit would become more significant in more severe climates."

Cellulose insulation benefits not covered by the University of Colorado study include:

- Cellulose contains more than 75% recycled material. In accordance with EPA Guideline 40 CFR Part 248 it is the preferred (and in some cases required) building thermal insulation for projects involving federal funds.

- Since production of cellulose requires much less energy than mineral fiber insulation, which is made in gas-fired furnaces, and foam plastics, which are petrochemicals, the "embodied" energy in cellulose is much lower per "R" of insulating value than other materials. From the national perspective these savings at the production stage must be added to the superiority of cellulose as an insulator.

If you're serious about saving money heating and cooling your home, about recycling and responsible use of resources, and about saving energy for our country the only insulation to seriously consider is cellulose.

Standards

Cellulose insulation is covered by the most comprehensive legal and voluntary standards of any insulation material. To be sold at all cellulose insulation must meet the requirements of the Consumer Product Safety Commission Safety Standard 16 CFR Part 1209. Most cellulose producers adhere to the much more stringent and comprehensive American Society for Testing and Materials Standard C-739 for loose-fill cellulose insulation and C-1149 for self-supporting spray-applied cellulose insulation. The Federal Trade Commission R-Value Rule applies to cellulose -- as it does to all residential thermal insulation.

A number of qualified independent product testing laboratories have cellulose insulation certification programs to assure contractors and consumers that the material they buy and install meets or exceeds government and industry standards. The National Association of Home Builders National Research Center certifies the quality and performance of cellulose insulation.

The labels of underwriters Laboratories, the United States Testing Company, or other NAVLAP-approved laboratories, or the seal of the NAHB National Research Center are reliable indicators of safe, effective cellulose insulation.

If you want insulation that is best for the nation,

for the environment, and for your checkbook,

choose CELLULOSE!

Scientists, engineers, and contractors have realized for many years that the most commonly-used building insulation materials are really not the best insulators. Now this "conventional wisdom" of energy conservation has been confirmed and quantified through scholarly research.

|

|